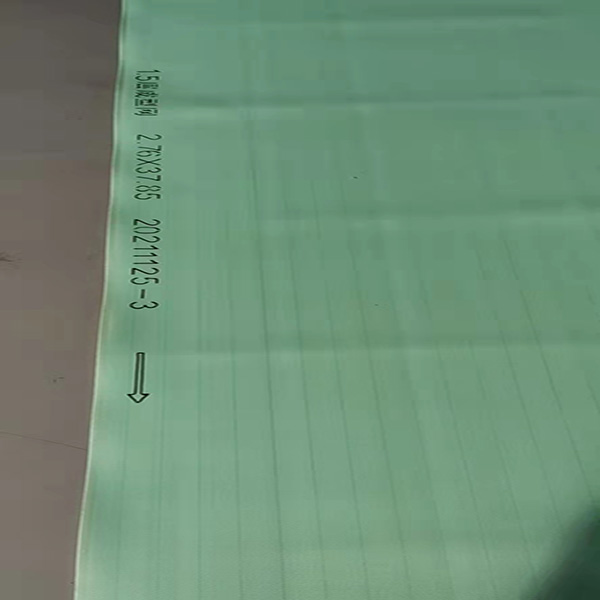

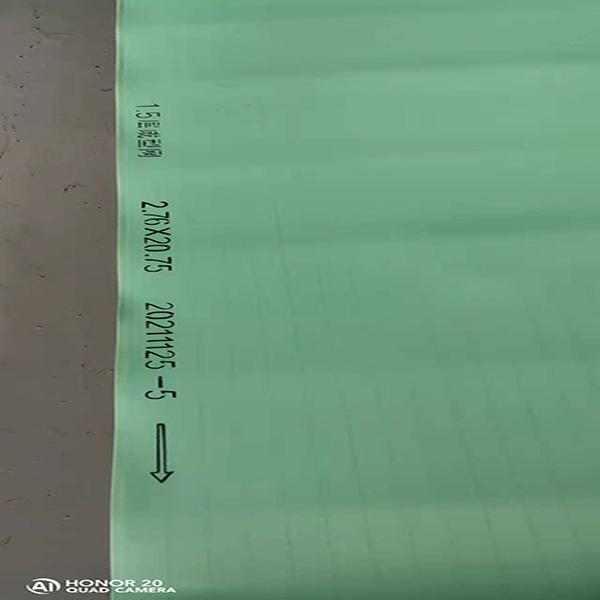

1.5 Layer forming fabric

Product Description:

1. According to the weaving, forming wire fabric can be divided into 3-shed, 4-shed. According to the category, it can be divided into one and a half layer, double layer and rectangular wire fabric. According to the joining mode, it can be divided into insert, pin, pin ring and spiral ring join.

2. 3-shed one layer and a half are suitable for drying papers below 70g.

3. 4-shed double layer fabric is suitable for drying papers above 70g.

4. flat wire dryer fabric is suitable for the fore several heating box of the drying zone, quality papers can use all.

Parameters of polyester paper machine 1.5 layer forming wire fabric for paper mill

Note: Customized based on customers’ requirement

Advantage:

1.Excellent fiber support

2.Good Sheet formation & tensile strength

3.Excellent guiding and dimensional stability

4.Cleaner running

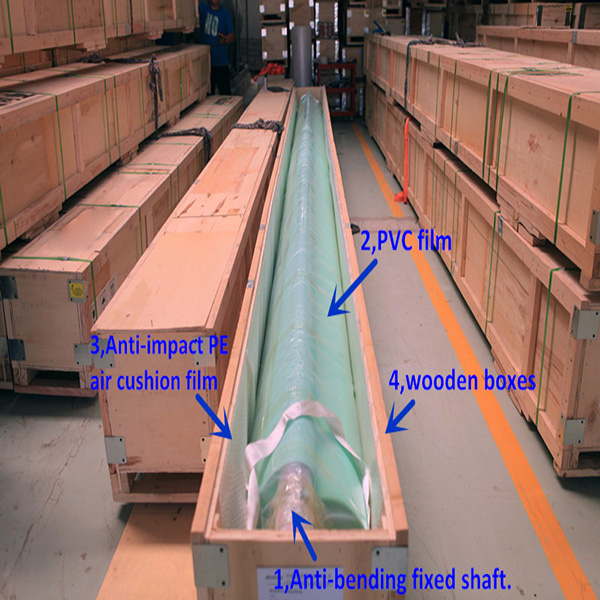

Technical Process

Application:

Polyester forming screen widely used in papermaking, industry drying, composite fabric production, food and medicine drying, transportation and other industries, the emergence of spiral nets effectively ensure the continuous production of modern industrial equipment, greatly improving production efficiency.

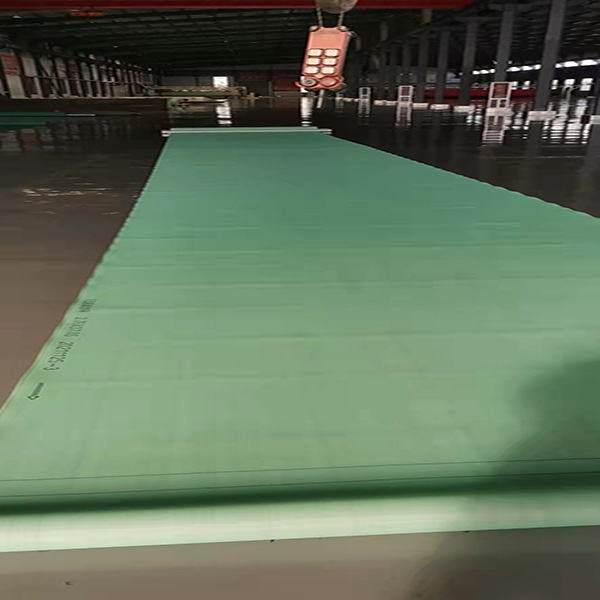

Work Shop:

Project:

paper making machine speed 1000m ,160g, kraft paper

Customer Feedbacks

Professional technical engineer dedicated to guide you

According to your actual needs, choose the most reasonable overall design and planning procedures