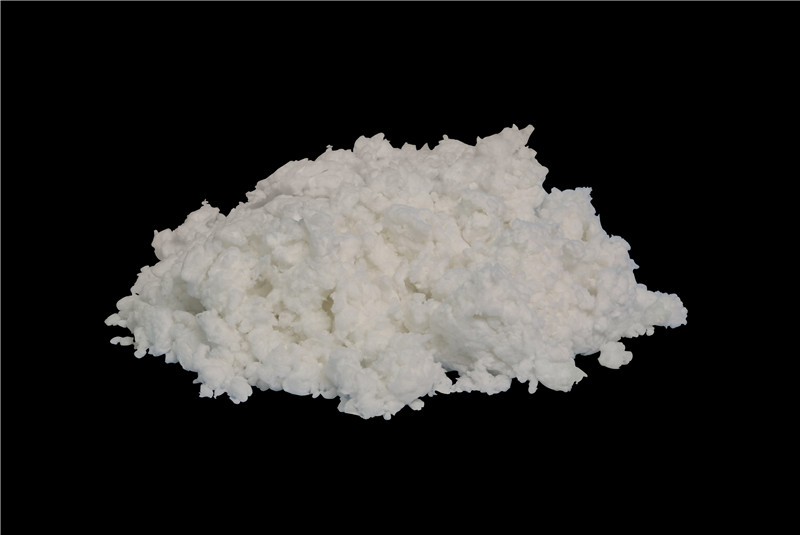

Ceramic Fiber Bulk/ RCF Bulk

Product Description

Bulk fiber is produced by melting high purity raw materials in resistance furnace, then adopt blown/spuning process, the bulk fiber is without secondary processing and heat treatment.

Typical features

Low heat capacity, low thermal conductivity

Excellent Thermal Stability

Excellent Chemical Stability

Binder free and Corrosion free

Excellent sound absorption

Typical Application

Feed material for blanket, board, textiles

Feed material of foam, castable, coating

High Temp gaskets sealing

Insulation in expansion joints

Feed material for wet processing products

Typical Product Properties

| Bulk Fiber | Normal Kaolin | Standard Purity | High Purity | High Al Purity | Lower AZS | Standard AZS | ||

| Temperature Grade℃ | 1050 | 1260 | 1260 | 1300 | 1300 | 1430 | ||

| Recommended Operating Temperature℃ | ≤950 | ≤1100 | ≤1150 | ≤1200 | ≤1200 | ≤1250 | ||

| Product Code | MYTX-PT-01 | MYTX-BZ-01 | MYTX-GC-01 | MYTX-GL-01 | MYTX-DG-01 | MYTX-HG-01 | ||

| Fiber Diameter(μm) | 3~5 | 3-5(Spun) | 3~5 | 2~4 | 3~5 | 3~5 | ||

| 2-4(Blown) | ||||||||

| Shot Content(Φ≥0.212mm)(%) | ≤20 | ≤20 | ≤20(Kaolin) | ≤15(HP) | ≤20(Kaolin) | ≤15(HP) | ≤15 | ≤15 |

| Al2 O3 | ≥40 | ≥43 | ≥44 | ≥52 | ||||

| Al2 O3 +SiO2 | ≥95 | ≥97 | ≥98.5 | ≥98.5 | ||||

| Al2 O3 +SiO2 +ZrO2 | ≥99 | ≥99 | ||||||

| ZrO2 | 5~7 | ≥15 | ||||||

| Fe2 O3 | ≤1.0 | ≤1.0 | ≤1.0(Kaolin) | ≤0.5(HP) | ≤1.0(Kaolin) | ≤0.5(HP) | ≤0.5 | ≤0.5 |

Note: Test data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes. The products listed comply to ASTM C892.

Professional technical engineer dedicated to guide you

According to your actual needs, choose the most reasonable overall design and planning procedures