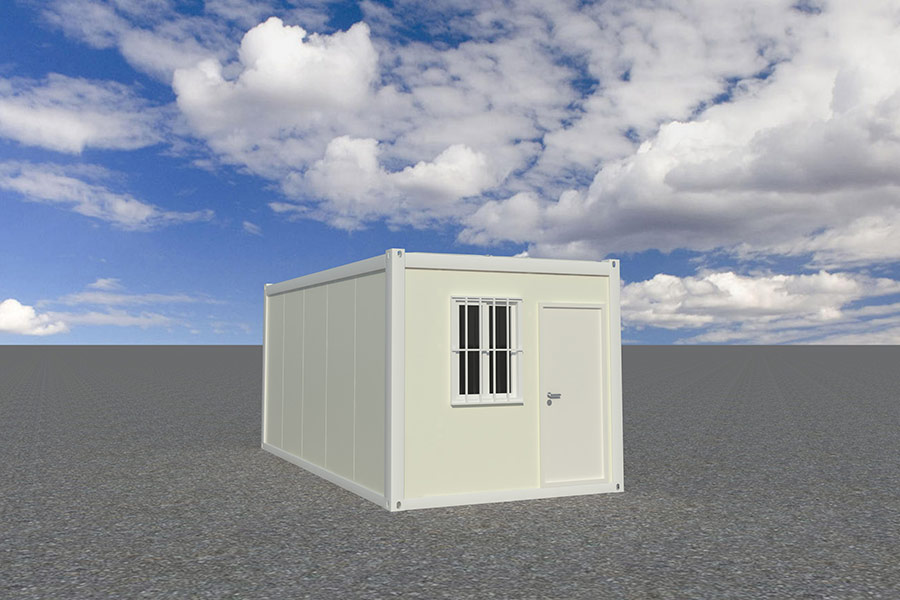

Multi-funtional Flat Packed Container Houses

Steel structure products are mainly made of steel, which is one of the main types of building structures. Steel is characterized by high strength, light weight, good overall rigidity and strong deformation capacity, so it is particularly suitable for building long-span, ultra-high and ultra-heavy buildings; The material has good plasticity and toughness, can have large deformation, and can well bear dynamic load; Short construction period; It has a high degree of industrialization and can carry out professional production with a high degree of mechanization.

The flat packed container house consists of upper frame components, bottom frame components, column and several interchangeable wall plates,and there’re 24 sets 8.8 class M12 high-strength bolts connect the upper frame & columns, column&bottom frame to form an integral frame structure, ensures the stability of the structure.

The product can be used alone, or form a spacious space through different combinations of horizontal and vertical directions. The house structure adopts the cold-formed galvanized steel, the enclosure and thermal insulation materials are all non combustible materials, and the water, heating, electrical, decoration and supporting functions are all prefabricated in the factory. No secondary construction is required, and it can be checked in after on-site assembly.

The raw material(galvanized steel strip)is pressed into the top frame&beam, bottom frame&beam and column by the roll forming machine through the programming of the technical machine,then polished and welded into the top frame and bottom frame. For galvanized components, the thickness of galvanized layer is >= 10um, and the zinc content is >= 100g / m3

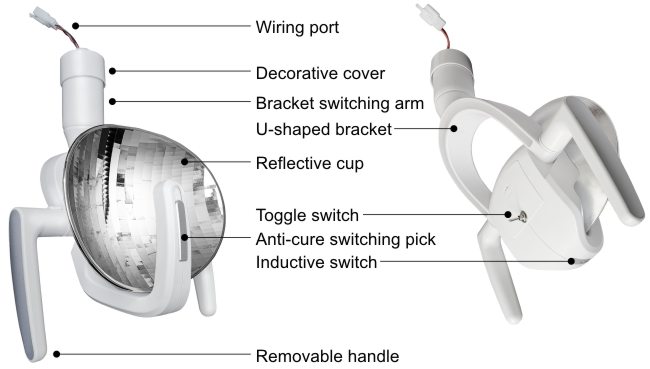

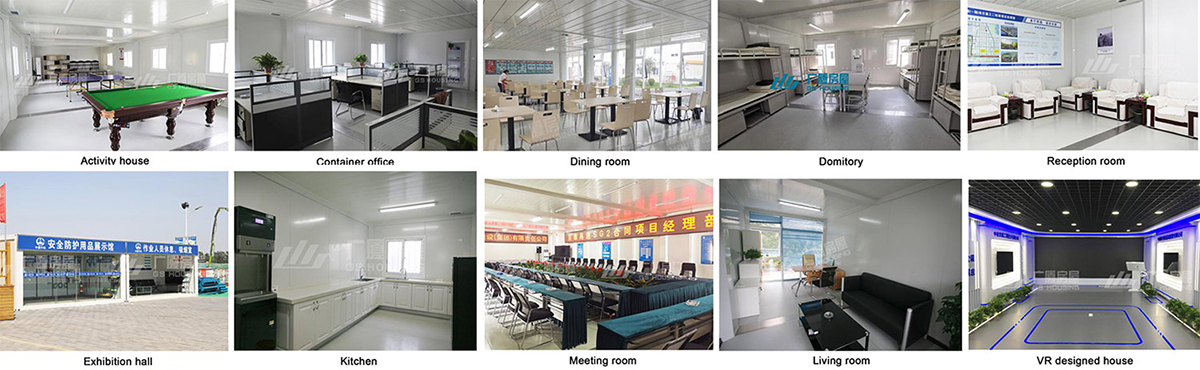

Internal Configuration

The Detail Processing of The Combined Houses

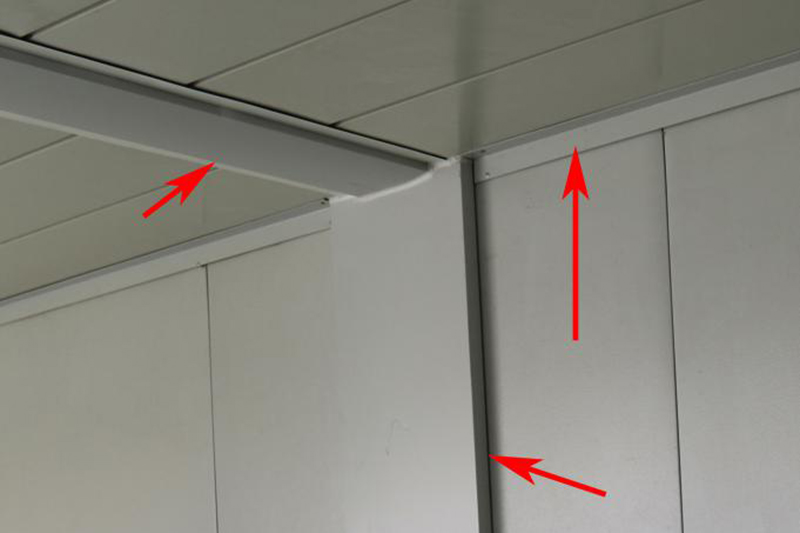

Skirting Line

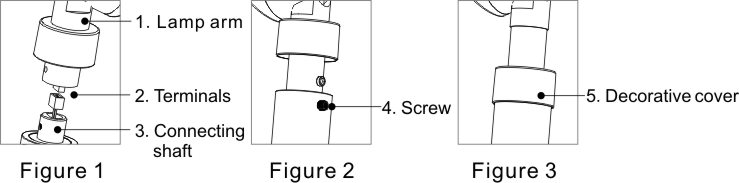

Connection Parts Among The Houses

SS Bindings Among The Houses

SS Bindings Among The Houses

Sealing Among The Houses